Introduction to Titanium

Titanium is a transition metal known for its high strength, light weight, and resistance to corrosion. It is as strong as steel but weighs only about half as much, making it an ideal material for applications where weight reduction is crucial without compromising strength.

Properties of Titanium:

- High Strength-to-Weight Ratio: Titanium’s strength is comparable to many types of steel, but it is significantly lighter.

- Corrosion Resistance: Titanium forms a passive oxide layer that protects it from corrosion, even in harsh environments.

- Biocompatibility: Titanium is non-toxic and biocompatible, making it suitable for medical implants.

- Temperature Resistance: Titanium maintains its properties at both extremely high and low temperatures.

Applications of Titanium Balls

Titanium balls leverage the unique properties of titanium to serve in a variety of high-performance applications.

Aerospace Industry:

Titanium for aircraft is widely used due to its light weight and high strength. Balls of titanium are essential in components such as bearings, actuators, and valve systems. Their corrosion resistance ensures reliability and longevity in the harsh environments of aerospace applications.

Medical Devices:

In the medical field, titanium’s biocompatibility makes it an excellent choice for surgical implants and medical devices. Titanium balls are used in joint replacements, dental implants, and other medical devices where durability and compatibility with the human body are critical.

Industrial Machinery:

Titanium balls are also used in industrial machinery, including pumps, valves, and precision instruments. Their durability and resistance to wear and corrosion make them suitable for demanding industrial environments.

Sports Equipment:

In sports equipment, titanium balls are utilized for their light weight and strength. They are used in high-performance equipment such as golf clubs and bicycles, where weight reduction can enhance performance.

Surprising Facts About Titanium

Titanium is a fascinating material with several surprising aspects that contribute to its widespread use:

Fact 1: Abundance and Extraction

Titanium is the ninth most abundant element in the Earth’s crust. However, it is challenging to extract and refine, which contributes to its high cost. The most common method of extraction is the Kroll process, which involves reducing titanium tetrachloride with magnesium.

Fact 2: Role in Space Exploration

Titanium has been a crucial material in space exploration. The Apollo lunar modules, for instance, utilized titanium components to reduce weight and ensure structural integrity. Titanium continues to be a key material in modern spacecraft and satellites.

Fact 3: Exceptional Corrosion Resistance

Titanium’s corrosion resistance is not limited to air; it also performs exceptionally well in seawater and chlorine environments. This makes it a preferred material in marine applications and chemical processing industries.

Fact 4: Biocompatibility

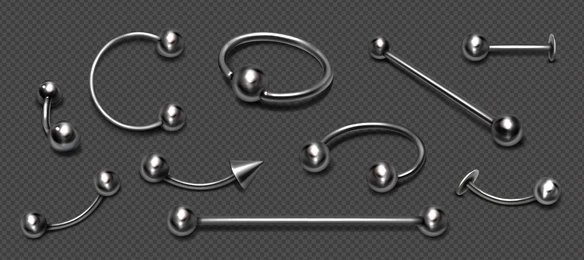

Titanium’s biocompatibility extends beyond medical implants. It is used in prosthetics and even in body piercings due to its non-reactive nature with human tissues.

Fact 5: Artistic and Architectural Uses

Beyond its industrial applications, titanium is also valued for its aesthetic qualities. It is used in high-end architectural designs and art installations. The Guggenheim Museum in Bilbao, Spain, features a stunning titanium-clad exterior, showcasing the metal’s beauty and durability.

Titanium Balls in Aircraft

Titanium balls play a vital role in the aerospace industry, particularly in aircraft design and manufacturing. Their use in aircraft components offers several benefits:

Weight Reduction:

Aircraft manufacturers are constantly seeking ways to reduce weight without compromising safety and performance. Titanium balls, being lightweight yet strong, contribute significantly to this goal. They are used in bearings and other critical components where weight savings can lead to improved fuel efficiency and reduced emissions.

Corrosion Resistance:

Aircraft are exposed to various environmental conditions, including moisture and salt air. Titanium’s corrosion resistance ensures that components remain reliable over long periods, reducing maintenance costs and increasing aircraft longevity.

High Temperature Tolerance:

Aircraft engines and other components often operate at high temperatures. Titanium balls can withstand these temperatures without losing strength or integrity, making them ideal for use in such environments.

Vibration and Noise Reduction:

Titanium balls are also used in systems designed to reduce vibration and noise within the aircraft. Their unique properties help in damping vibrations and minimizing noise, enhancing passenger comfort and aircraft performance.

FAQs

What are the main benefits of using titanium balls in industrial applications?

Titanium balls offer high strength, light weight, corrosion resistance, and biocompatibility, making them suitable for various demanding industrial applications, including aerospace, medical devices, and industrial machinery.

How does the cost of titanium balls compare to other materials?

Titanium balls are generally more expensive than balls made from materials like steel or aluminum due to the complexity of extracting and processing titanium. However, their superior properties often justify the higher cost in high-performance applications.

Can titanium balls be used in high-temperature environments?

Yes, titanium balls are suitable for high-temperature environments as they maintain their strength and integrity even at elevated temperatures. This makes them ideal for use in aerospace and industrial applications.

Why are titanium balls preferred in medical implants?

Titanium’s biocompatibility, non-toxicity, and corrosion resistance make it an excellent material for medical implants. Titanium balls are used in joint replacements and other medical devices where compatibility with the human body is crucial.

What makes Abbott Ball’s titanium balls unique?

Abbott Ball’s titanium balls are manufactured with precision and adhere to the highest quality standards. Their expertise in producing high-performance titanium balls ensures reliability and superior performance in various applications, making them a trusted choice in the industry.

Conclusion

Titanium balls are an extraordinary example of how a single material can revolutionize multiple industries. Their unique combination of strength, light weight, corrosion resistance, and biocompatibility makes them indispensable in aerospace, medical, industrial, and even sports applications. As technology advances, the demand for high-performance materials like titanium is set to grow, further cementing its place in the world of engineering and design. Abbott Ball continues to lead the way in producing top-quality titanium balls, meeting the evolving needs of various high-tech industries.