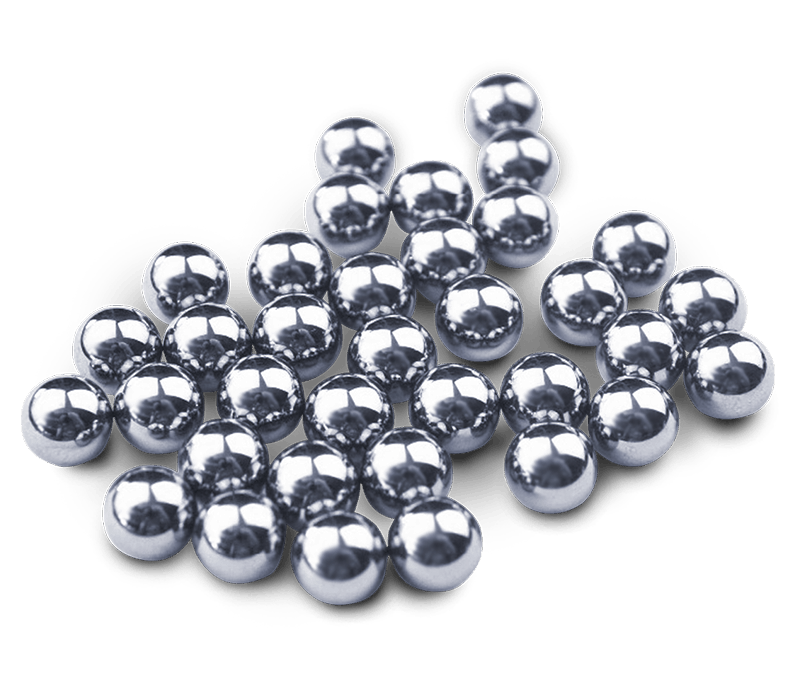

ASIA Type 52100 Chrome Steel Balls are used in the ball and roller bearing industry and for a variety of automobile applications. These Chrome Steel Balls have excellent surface quality. They offer superior wear resistance, high hardness and high load bearing capacity as a result of through-hardening.

| AISI Type 52100 Chrome Steel Balls | |||

| SIZE RANGE | 0.80mm (1/32″) up to 2-1/2″ | ||

| GRADES: | 3, 5, 10, 25, 50, 100, 500, 1000, 2000 | ||

| CHEMICAL COMPOSITION | |||

| CHROMIUM | 1.30% TO 1.60% | ||

| CARBON | .98% TO 1.10% | ||

| MANGANESE | 0.25% TO 0.45% | ||

| SILICON | 0.15% TO 0.35% | ||

| PHOSPHOROUS | 0.025% MAX. | ||

| SULPHUR | 0.025% MAX. | ||

| MECHANICAL PROPERTIES | |||

| TENSILE STRENGTH | 325,000 PSI | ||

| YIELD STRENGTH | 295,000 PSI | ||

| ELONGATION IN TWO INCHES | 5% | ||

| REDUCTION IN AREA | 8% | ||

| MODULUS OF ELASTICITY | 29,500,000 PSI | ||

| DENSITY | .283 LBS./CU.IN. | ||

| PHYSICAL CHARACTERISTICS | |||

| CORROSION RESISTANCE | NO CORROSION RESISTANCE | ||

| MAGNETIC | |||

| GENERAL USAGE | |||

| QUICK DISCONNECT COUPLINGS, AUTOMOTIVE APPLICATIONS, BALL BEARING & ROLLER BEARING | |||

Chrome Steel Balls

We, at Abbott Ball Company are a distinguished chrome steel ball manufacturer, offer high-quality steel balls perfect for various industrial applications.

With excellent surface quality and high hardness, our products ensure superior wear resistance, making them ideal for demanding environments where durability is critical.

Types of Products We Offer

Our offerings cater to various applications, ensuring precision and durability in every sphere.

52100 Chrome Steel Balls

Renowned for their exceptional wear resistance and strength, these are a prime choice for bearings and other heavy-duty applications.

With excellent surface finish and hardened properties, they ensure optimal performance under stress

Customizable Options

Beyond our 52100 series, we provide a range of customized solutions tailored to specific requirements.

Whether you need enhanced corrosion resistance or particular size specifications, our team is equipped to deliver with precision engineering.

Primary Applications of Chrome Steel Balls

Aerospace

Chrome steel balls are pivotal in aerospace applications, providing high load bearing capabilities and excellent surface quality which ensure reliable performance under extreme conditions. Their use in precision components helps in maintaining the structural integrity of aerospace assemblies.

52100 Chrome Steel Balls

Renowned for their exceptional wear resistance and strength, these are a prime choice for bearings and other heavy-duty applications. With excellent surface finish and hardened properties, they ensure optimal performance under stress.

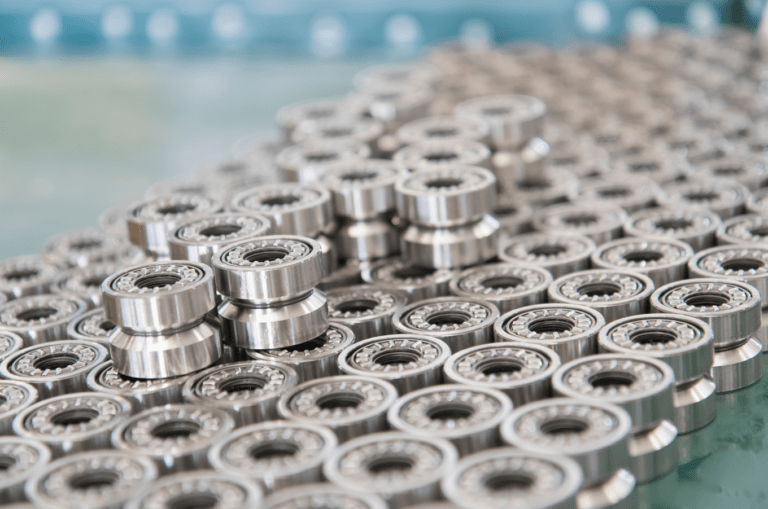

Automotive Applications

Chrome ball bearings are utilized extensively in the automotive industry due to their robustness and high load capacity, enhancing the performance and durability of vehicle components such as transmissions and steering assemblies.

Ball & Roller Bearings

Ball and roller bearing assemblies rely on high chrome balls for their exceptional mechanical properties, including high tensile strength and toughness, which are critical for handling heavy loads and reducing friction in moving parts.

Linear Bearings

Chrome steel ball bearings facilitate smooth and precise movement in linear bearings, commonly used in various machinery and automation systems.

Their resistance to wear and deformation is crucial for maintaining accuracy over time.

Valves

In valves, the use of chrome steel balls is critical due to their ability to withstand high pressures and corrosive environments, ensuring reliable valve operations and extended service life in industrial and residential plumbing systems.

Advantages of Using Chrome Ball Bearings

Cost-Effectiveness

They provide a cost-efficient solution due to their durability and extended service life, reducing the need for frequent replacements.

Enhanced Performance

Precise manufacturing ensures smooth operation and high rotational accuracy, which improves the overall performance of machinery.

Low Maintenance Requirements

Due to their robust design and resistance to wear and tear, these bearings require less maintenance compared to other types of bearings, which can lead to lower operational costs.

Improved Energy Efficiency

The excellent surface quality reduces friction between moving parts, leading to lower energy consumption and better fuel efficiency in automotive applications.

Wide Temperature Range

They can operate effectively under a wide range of temperatures, making them suitable for applications in varying environmental conditions without performance degradation.

Frequently Asked Questions

A: We offer a wide range of sizes, from as small as 0.80mm (1/32″) up to 2-1/2″, catering to various industrial needs and specifications.

A: The grade number indicates the tolerance and sphericity of the balls. Lower numbers (such as 3 or 5) represent higher precision and are used in applications requiring the utmost accuracy, like aerospace bearing applications.

A: These balls consist of 1.30% to 1.60% Chromium and 0.98% to 1.10% Carbon, enhancing their hardness and wear resistance. They also contain manganese and silicon and have low levels of Phosphorus and Sulphur to improve strength and durability.

A: Our steel balls meet stringent international standards, including IATF 16949:2016 and ISO 14001:2015, ensuring high quality and consistency in automotive and environmental management applications.

A: Proper storage is crucial for maintaining the quality. Here’s how to do it:

- Keep Dry: Store in a moisture-free area to prevent rust.

- Control Temperature: Avoid extreme temperature changes.

- Protect Surfaces: Use non-abrasive materials for storage.

- Separate Grades: Store different sizes or grades apart.

- Inspect Regularly: Check periodically for any signs of damage.

A: Abbott Ball Company typically processes and ships within 4 to 6 weeks. The exact timeline can vary based on the specifics of the order and current production schedules.

Customers are encouraged to contact our customer service team for the most accurate and up-to-date information regarding their order status and specific lead times.

A: The life expectancy can vary significantly based on the application, load, operating conditions, and maintenance practices. Under optimal conditions with proper lubrication and minimal contamination, these balls can last for years even in high-load applications. Regular maintenance and appropriate environmental conditions are key to maximizing their lifespan.

A: Yes, we can accommodate custom orders. Our manufacturing flexibility allows us to produce chrome steel balls to meet specific customer requirements regarding size, grade, and quantity.

A: Choosing the right grade depends on your specific application requirements, including load capacity, environmental conditions, and required precision. Abbott Ball’s technical team can assist in selecting the most appropriate grade based on your use case.

A: While the high chrome balls are durable and wear-resistant, they are not typically used in food processing equipment due to their limited corrosion resistance and potential health hazards from chromium leaching. Stainless steel balls are preferred in such applications for their superior corrosion resistance and food safety compliance.

Abbott keeps the ball rolling.

Abbott Ball will help you achieve lower cost, quicker turnaround and the highest quality production possible. We are poised to help you create innovative new ways to serve existing markets and new levels of expertise for emerging markets.