Abbott steel media in vibratory, barrel and tumbling finishing equipment reduces material and media costs while it improves productivity and quality. Abbott steel media can last indefinitely depending on the application and care of the media, often with a payback at less than a year. Operations that were formally performed by hand on burr benches or in multiple machines are now done with one, versatile process and steel media. Abbott steel finishing media produces fewer part rejects from lodging. Better- fitting parts also reduces assembly time and increase wear resistance in moving assemblies. Steel media works with biodegradable compounds and does not contribute soils in the waste stream. Abbott has an onsite lab that can test your part out to see which type of media will provide the best results without lodging.

Why Steel Media?

Works Harder - Lasts Longer

The substantial weight of steel media exerts higher pressure to a mass of components in vibratory, barrel and tumbling finishing equipment. As workpieces force their way and vibrate through this mass, the increased pressure and resistance from steel media is especially effective in reducing finishing times.

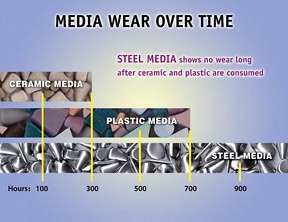

Steel is also a non-consumable media. With proper care, it is not “used up” in the finishing process. Its durability and increased working pressure make steel the ideal media for a variety of finishing processes. Furthermore, wastewater treatment is limited to removal of the soils generated from your parts only: steel does not create or absorb soils from wear, as do other media.

Imparts Compressive Stress

As steel media impinges on a part, its surface is work-hardened. The working action imparts compressive stress as a beneficial byproduct of the finishing process. In many instances, the process can replace steel shot-blasting as a work-hardening step. Parts processed with steel media have longer cycle lives and greater resistance to wear as a result of this compressive stress action.

Improves Pre-Plate Finishing

Parts that appear smooth are actually characterized by micro-imperfections, which cause plating problems. The weight of steel media flattens these minute irregularities and prepares a surface for more satisfactory plating. This action is especially critical during the deposition of nickel or other solutions that typically do not fill the depressions, but follow the higher contours of the metal.

Reduces Porosity on Plated Parts

Financial Advantage

Steel Media is considered a capitalized investment instead of a consumable expense because it typically lasts twenty years or longer.