Abbott offers carburized balls and case hardened carbon steel balls. Carbon balls in the soft stage with no heat treatment are also available. Through-hardened carbon balls are available upon request. Balls with both low and high carbon content are also offered. Abbott carbon steel balls are used in automotive applications, for semi-precision bearings, and in commercial applications such as casters, locks, and drawer slides. Other applications for carbon steel balls include locks, bicycles, roller skates, slides, trolleys and conveyors.

| AISI Type 1018 Carbon Steel Balls | |||

| SIZE RANGE | 1.0mm (.040″) up to 2-1/2″ | ||

| GRADES: | 100, 500, 1000, 2000 | ||

| CHEMICAL COMPOSITION | |||

| CARBON | .15% – .20% | ||

| MANGANESE | .6% – .9% | ||

| PHOSPHOROUS | .03% MAX. | ||

| SULPHUR | .05% MAX. | ||

| MECHANICAL PROPERTIES | |||

| HARDNESS | RC 60 min. | ||

| PHYSICAL CHARACTERISTICS | |||

| CORROSION RESISTANCE | NOT CORROSION RESISTANCE | ||

| GENERAL USAGE | |||

| BEARINGS, AUTOMOTIVE AND COMMERCIAL APPLICATIONS SUCH AS CASTORS, LOCKS, AND DRAWER SLIDES | |||

| AISI Type 1015 Carbon Steel Balls | |||

| SIZE RANGE | 1.0mm (.040″) up to 2-1/2″ | ||

| GRADES: | 100, 500, 1000, 2000 | ||

| CHEMICAL COMPOSITION | |||

| CARBON | .13% – .18% | ||

| MANGANESE | .3% – .6% | ||

| PHOSPHOROUS | .04% MAX. | ||

| SULPHUR | .05% MAX. | ||

| MECHANICAL PROPERTIES | |||

| HARDNESS | RC 60 min. | ||

| PHYSICAL CHARACTERISTICS | |||

| CORROSION RESISTANCE | NOT CORROSION RESISTANCE | ||

| GENERAL USAGE | |||

| BEARINGS, AUTOMOTIVE AND COMMERCIAL APPLICATIONS SUCH AS CASTORS, LOCKS, AND DRAWER SLIDES | |||

| Softballs – 1018 Steel | |||

| SIZE RANGE | 1.0mm (.040″) up to 2-1/2″ | ||

| GRADES: | 100, 500, 1000, 2000 | ||

| CHEMICAL COMPOSITION | |||

| CARBON | .15% – .20% | ||

| MANGANESE | .6% – .9% | ||

| PHOSPHOROUS | .04% MAX. | ||

| SULPHUR | .05% MAX. | ||

| MECHANICAL PROPERTIES | |||

| HARDNESS | N.A. | ||

| PHYSICAL CHARACTERISTICS | |||

| CORROSION RESISTANCE | NOT CORROSION RESISTANCE | ||

| GENERAL USAGE | |||

| WELDING CAPABILITIES, DECORATIVE | |||

Carbon Balls

At Abbott Ball Company, we expertly produce carbon steel balls, available in carburized, case-hardened, or soft forms, catering to diverse industrial needs.

From automotive to commercial applications like casters and locks, our products are precision-crafted in various grades and sizes, ensuring high performance and durability across multiple sectors.

Types of Products We Offer

AISI 1010/1015 Low Carbon Steel Balls

These balls are case-hardened, balancing malleability and wear resistance, suitable for applications requiring moderate hardness and toughness. They come in sizes ranging from 0.5mm to 50.8mm, with hardness levels between HRC 55-65.

AISI 1085 High Carbon Steel Balls

Forged from high-carbon steel, these through-hardened balls provide superior hardness and wear resistance. They are ideal for high-stress applications, available from 1.5mm to 50.8mm in diameter, with hardness ranging from HRC 59-66.

Primary Applications of Carbon Balls

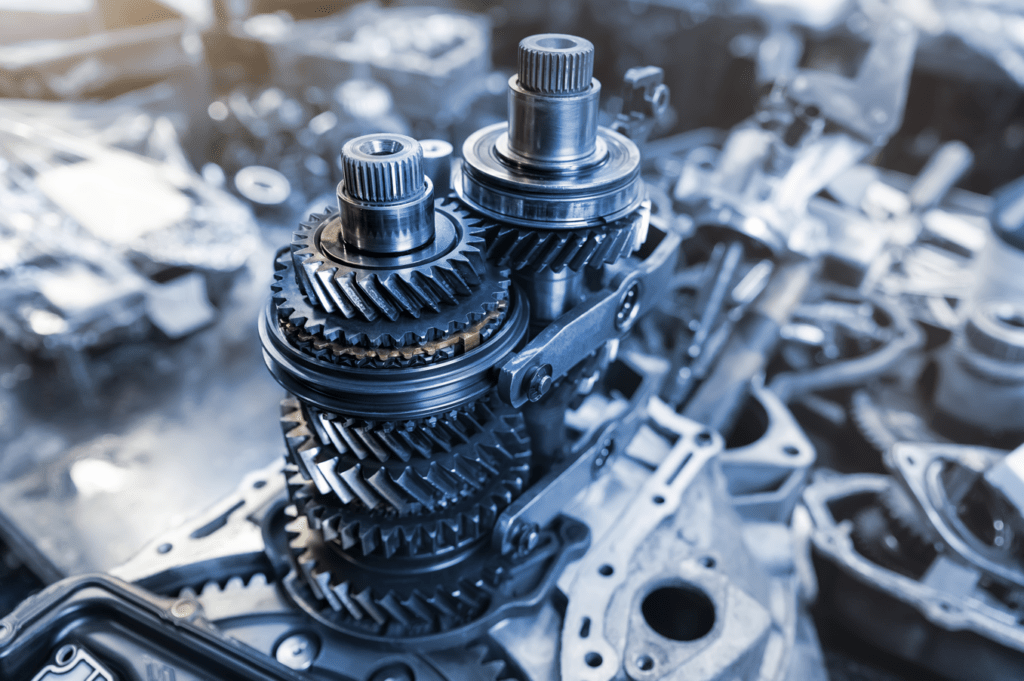

Automotive Applications

Carbon steel ball bearings are integral in automotive components, such as wheel bearings, transmissions, and steering assemblies.

Their ability to handle high temperatures and pressures makes them indispensable for enhancing vehicle reliability and longevity.

Semi-Precision Bearings

Mild steel ball bearings are used in applications that demand moderate precision but must endure robust conditions, such as in agricultural equipment and industrial conveyor systems. These bearings strike an effective balance between performance and cost.

Casters, Locks, Drawer Slides

Low-carbon steel balls are favored in mechanical systems like casters, locks, and drawer slides for their smooth operation and durability.

These balls ensure longevity and require minimal maintenance, making them suitable for various mechanical applications.

Pinball Machines and Toys

Carbon steel spheres are essential in entertainment devices like pinball machines and toys, where their durability and precise performance are crucial for ensuring continuous, high-impact use without failure.

Roller Skates and Skateboards

High carbon steel ball bearings are employed in sports equipment such as roller skates and skateboards.

Their high resistance to deformation under stress ensures smooth rolling and better durability, enhancing both performance and safety.

Trolleys & Conveyors

Carbon steel bearing balls are crucial for the smooth and efficient operation of trolleys and conveyors in industrial settings.

They help in reducing friction and wear on machinery, which is vital for maintaining high operational efficiency and reducing downtime.

Ball Plugs and Ball Valves

Carbon balls excel in applications such as ball plugs and ball valves where their hardness and resistance to compressive forces make them reliable for controlling fluid flow in industrial piping systems.

Drill Balls

Carbon steel balls are used extensively in drilling and mining.

Their impact resistance is essential for effectively breaking through tough materials, thereby optimizing drilling operations.

Advantages of Using Carbon Balls

They offer a range of benefits that make them a preferred choice in numerous industrial applications.

Here’s a few of them:

-

Cost-Effective

Provides a budget-friendly option compared to other materials, while maintaining high performance.

-

Minimal Maintenance

Their resilience ensures longevity, minimizing the need for frequent replacements or repairs.

-

Scalability in Production

They can be produced on a large scale efficiently, which benefits industries requiring large quantities.

-

Customizable

Available in various sizes and grades to meet specific needs, enhancing their applicability across industries.

Frequently Asked Questions

A: We offer multiple grades, including 100, 500, 1000, and 2000. These grades indicate the precision and quality of the balls, catering to different industry requirements for both performance and application specificity.

A: Common signs include visible wear such as pitting or scoring, unusual noise during operation, increased vibration, and a decrease in performance efficiency. Regular inspection and replacing them as needed can prevent machinery failure and maintain operational standards.

A: They are available in a size range from 1.0mm (.040″) up to 2-1/2″. This size range allows for a wide variety of uses in different equipment and mechanisms across industries.

A: Since they are not corrosion-resistant, it is crucial to store them in a dry environment and ideally with rust-preventive coatings or oils. Proper packaging can also prevent exposure to moisture that might lead to rusting.

A: Quality assurance at Abbott Ball Company involves rigorous testing and inspection processes, including dimensional accuracy, hardness testing, and smoothness of finish. Each batch of bearings undergoes multiple quality checks to ensure they meet our high standards and customer expectations.

A: The lead time for bulk orders can vary depending on the specifics of the order and current production schedules. However, we strive to accommodate customer timelines and can offer expedited services for urgent requirements.

For the most accurate lead time, contact our customer service.

A: The selection of the right grade and size depends on the application’s specific requirements for precision, load-bearing capacity, and environmental conditions. Consulting with our technical team can help clarify these needs, and we can recommend the most suitable specifications based on the intended usage and operational conditions.

A: They are certified under IATF 16949:2016 and ISO 14001:2015, ensuring compliance with international quality and environmental management standards.

A: Yes, they are suitable for high-speed applications, especially the through-hardened varieties, which are designed to handle high levels of stress and kinetic energy without deforming.

A: Yes, Abbott Ball Company offers customization options in terms of sizes and grades to meet specific application requirements. Customers can discuss their specific needs with our team to ensure they receive the most suitable product for their particular industrial or commercial application.

Abbott keeps the ball rolling.

Abbott Ball will help you achieve lower cost, quicker turnaround and the highest quality production possible. We are poised to help you create innovative new ways to serve existing markets and new levels of expertise for emerging markets.