Brass balls exhibit good corrosion resistance in environments where fuel oil, gasoline, kerosene, and alcohol are present. Brass is a non-ferrous material. Brass balls provide excellent resistance to corrosion by water. Brass also exhibits excellent electrical conductivity. Abbott manufactures Brass balls for the automotive and electronic industries. Abbott brass balls are also widely used in the security and appliance industries for dip and tilt switches. Brass balls are available in a range of sizes, tolerances and grades of brass.

| BRASS CDA 260 | |||

| SIZE RANGE | 0.50mm (.020″) up to 1-5/16″ | ||

| GRADES: | 100, 200, 500, 1000 | ||

| CHEMICAL COMPOSITION | |||

| COPPER | 0.70% | ||

| ZINC | 0.30% | ||

| MECHANICAL PROPERTIES | |||

| HARDNESS | RB 75-87 | ||

| SURFACE FINISH | 6-8 MICRO FINISH | ||

| PHYSICAL CHARACTERISTICS | |||

| CORRSION RESISTANT | YES | ||

| ELECTRICAL CONDUCTIVITY | |||

| GENERAL USAGE | |||

| VALVES, ELECTRONICS, AUTOMOTIVE SECURITY, APPLIANCES | |||

Brass Balls

Brass balls exhibit good corrosion resistance in environments where fuel oil, gasoline, kerosene, and alcohol are present. Brass is a non-ferrous material that provides excellent resistance to corrosion by water and also exhibits excellent electrical conductivity.

Abbott manufactures Brass balls for the automotive and electronic industries. Also widely used in the security and appliance industries for dip and tilt switches. From small brass balls to giant brass balls, we’ve wide range of sizes, tolerances and grades of brass.

Types of Products We Offer

Hollow Brass Balls

Perfect for applications where weight is a concern without compromising on the material’s integrity. They are used extensively in float valves, light fixtures, and artistic sculptures, providing both functionality and aesthetic charm.

Threaded Brass Balls

Equipped with internal or external threads making them suitable for applications requiring easy assembly and disassembly. Commonly used in automotive applications and fittings, providing robust performance with excellent corrosion resistance.

Primary Applications of Carbon Balls

Valve Components

Brass balls are extensively used in the production of valves, especially for applications requiring corrosion resistance and metal-to-metal sealing capabilities.

The natural properties of brass make it ideal for regulating and controlling fluids in a variety of systems, including plumbing, automotive, and industrial machinery.

Electrical Conductors

Due to its excellent electrical conductivity, brass balls are often utilized in electrical engineering, particularly in applications like contact points in switches and relays.

They provide reliable conductivity and durability, ensuring efficient and long-lasting performance in electrical systems.

Bearing Balls

Brass balls are used as bearing balls in applications where low friction and longevity are required. Their resistance to spark and corrosion makes them suitable for environments where rust and degradation are a concern, such as marine and underwater settings.

Decorative Applications

Highly polished brass balls are used in decorative applications for their aesthetic appeal.

They are commonly found in furniture, architectural details, and art installations, where they add a touch of elegance and distinction due to their shiny, gold-like appearance.

Automotive Systems

In automotive systems, brass balls are used within fuel injection systems and other critical engine components where durability and resistance to heat are vital.

They help ensure the smooth operation of mechanisms within the high-stress environment of automotive engines.

Aerospace Components

The aerospace industry uses huge brass balls in applications requiring robust materials that resist corrosion and reduce sparking.

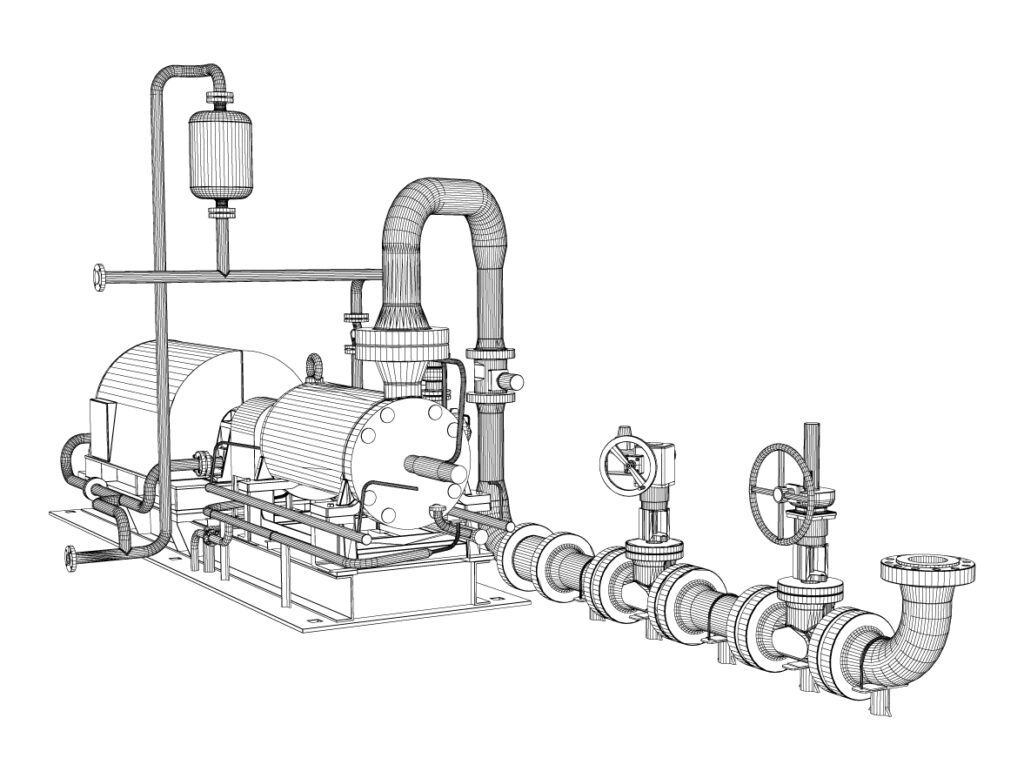

Fluid Control Systems

Brass balls play a crucial role in fluid control systems such as hydraulic and pneumatic systems.

They are often used as check valves and flow control units, where their capacity to withstand varying temperatures and pressures is essential for system integrity and functionality.

Marine Applications

Huge brass balls are ideal for marine applications due to their resistance to corrosion from saltwater.

They are used in fittings, valves, and navigational instruments aboard ships and boats, ensuring longevity and reliability in harsh marine environments.

Advantages of Using Brass Balls

They offer a range of benefits that make them a preferred choice in numerous industrial applications.

Here’s a few of them:

Versatility

Demonstrated by their wide range of applications across various industries, including automotive, aerospace, and fluid control systems. Their durability and resistance to temperature variations make them a reliable choice for many different uses.

Machinability

Known for its excellent machinability, allowing for precise and efficient manufacturing of brass balls. This leads to high-quality products with smooth finishes, ideal for both industrial applications and consumer products.

Aesthetic Appeal

Brass has a distinctive, bright gold-like appearance that enhances the visual appeal of any application. Brass balls are often used in decorative and architectural applications to add a touch of elegance and luxury.

Electrical Conductivity

Highly conductive, making ideal for applications requiring good electrical conductivity, such as electrical components and connectors. This ensures efficient and reliable performance in electrical systems.

Corrosion Resistance

Excellent resistance to rust and corrosion, making them suitable for use in harsh environments, including those exposed to moisture and chemicals. This property extends the lifespan of products and reduces maintenance needs.

Frequently Asked Questions

A: Absolutely. Brass balls can be produced in different sizes and finishes depending on the specific requirements of the application. This includes options for polishing, threading, and even hollow configurations.

A: Brass balls add an elegant and classic aesthetic to iron beds. They are also corrosion-resistant, which helps prevent rust and maintain the bed’s appearance over time. The shiny finish of brass complements the iron, enhancing the overall look of the bed.

A: Brass balls offer superior corrosion resistance compared to steel balls but generally have a lower hardness and wear resistance. This makes them better suited for applications where corrosion resistance is more important than high mechanical strength.

A: Brass balls require minimal maintenance due to their resistance to tarnishing and corrosion. Regular cleaning to remove dirt and debris is generally sufficient to maintain their condition and performance.

A: Brass balls are highly durable and resistant to corrosion and tarnishing, making them an excellent choice for both indoor and outdoor beds. Their robustness ensures they last as long as the bed itself with minimal care.

A: Brass balls are typically manufactured through a forging process where brass is heated and then shaped into spherical forms. They are then polished to achieve the desired finish and inspected for quality.

A: While brass balls are highly versatile, they are not suitable for applications requiring extremely high hardness or load-bearing capacity, such as in heavy-duty mechanical bearings.

A: Yes. We offer customization options for brass balls. You can request specific diameters, finishes, and even threaded brass balls or hollow versions depending on your project requirements.

Abbott keeps the ball rolling.

Abbott Ball will help you achieve lower cost, quicker turnaround and the highest quality production possible. We are poised to help you create innovative new ways to serve existing markets and new levels of expertise for emerging markets.