Table of Contents

- Introduction

- What is a Bearing Housing?

- Types of Bearing Housings

- Materials Used in Bearing Housings

- Key Factors to Consider When Choosing a Bearing Housing

- Common Applications of Bearing Housings

- Benefits of Using Quality Bearing Housings

- How to Maintain Bearing Housings

- Conclusion

- FAQs

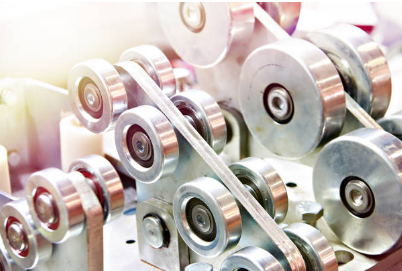

Introduction

Bearing housings are critical components in various mechanical systems, providing support and protection for bearings, ensuring their optimal performance and longevity. The right bearing housing not only enhances the efficiency of the equipment but also minimizes maintenance costs and downtime.

This comprehensive guide will help you understand the different types of bearing housings, the materials used in their construction, and the key factors to consider when choosing the appropriate bearing housing for your specific needs.

What is a Bearing Housing?

A bearing housing, also known as a bearing block or bearing pedestal, is a component designed to house a bearing and provide it with secure positioning and protection against contaminants and mechanical damage. Bearing housings are essential in many applications where rotational motion is involved, such as in machinery, automotive systems, and industrial equipment. They ensure that bearings remain in alignment, maintain their performance, and have a longer operational lifespan.

Types of Bearing Housings

Bearing housings come in various designs to suit different applications. The most common types include:

- Pillow Block Housings

Pillow block housings are one of the most widely used types of bearing housings. They are designed to provide support for a rotating shaft and are typically mounted on a flat surface. These housings are versatile and can accommodate a wide range of bearing types and sizes.

- Flange Housings

Flange housings are mounted using flanges, which provide additional support and stability. These housings are often used in applications where the bearing needs to be mounted against a vertical or horizontal surface. Flange housings come in various designs, including two-bolt, four-bolt, and tapped-base configurations.

- Take-up Housings

Take-up housings are designed for applications that require adjustable bearing positioning, such as conveyor systems. These housings allow for easy adjustment of the bearing position to accommodate changes in belt tension or alignment.

Cartridge Housings

Cartridge housings are compact and enclosed designs that provide excellent protection for bearings against contaminants. These housings are often used in applications with high levels of dust, dirt, or moisture, such as in agricultural or construction equipment.

Materials Used in Bearing Housings

The material of a bearing housing is crucial for its performance, durability, and suitability for specific applications. Common materials include:

- Cast Iron

Cast iron is a popular choice for bearing housings due to its excellent strength, durability, and cost-effectiveness. It is suitable for a wide range of applications and can withstand significant loads and harsh operating conditions.

- Stainless Steel

Stainless steel bearing housings offer superior resistance to corrosion and are ideal for applications in harsh environments, such as marine, food processing, and chemical industries. They provide excellent durability and longevity but are generally more expensive than cast iron housings.

- Thermoplastics

Thermoplastic bearing housings are lightweight, corrosion-resistant, and suitable for applications requiring hygiene and cleanliness, such as in the food and pharmaceutical industries. These housings are not as strong as metal housings but offer adequate performance for many applications.

- Bronze

Bronze bearing housings are known for their excellent wear resistance and low friction properties. They are commonly used in high-load, low-speed applications where durability and reliability are critical.

Key Factors to Consider When Choosing a Bearing Housing

Selecting the right bearing housing involves considering several key factors to ensure optimal performance and longevity:

- Load Capacity

The load capacity of the bearing housing must match the demands of the application. Overloading a bearing housing can lead to premature failure and increased maintenance costs.

- Environmental Conditions

Consider the operating environment when choosing a bearing housing. Factors such as temperature, moisture, dust, and chemicals can affect the performance and lifespan of the housing. Choose materials and designs that can withstand these conditions.

- Installation and Maintenance

Ease of installation and maintenance is another important consideration. Bearing housings that are easy to install and maintain can reduce downtime and maintenance costs, enhancing overall efficiency.

- Cost

While cost is always a factor, it is important to balance initial costs with long-term benefits. Investing in high-quality bearing housings can lead to lower maintenance costs, reduced downtime, and improved equipment performance.

Common Applications of Bearing Housings

Bearing housings are used in a wide range of applications across various industries. Some common applications include:

- Automotive Industry

In the automotive industry, bearing housings are used in engines, transmissions, and suspension systems to ensure smooth and reliable operation.

- Industrial Machinery

Bearing housings are critical components in industrial machinery, such as conveyor systems, pumps, and compressors, where they provide support and protection for rotating shafts and bearings.

- Agricultural Equipment

Agricultural equipment, such as tractors and combines, rely on bearing housings to maintain the performance and durability of their mechanical systems in demanding environments.

- Construction Equipment

Construction equipment, including excavators and bulldozers, use bearing housings to ensure the reliability and efficiency of their hydraulic and mechanical systems.

Benefits of Using Quality Bearing Housings

Using high-quality bearing housings offers several benefits, including:

- Enhanced Durability

Quality bearing housings are designed to withstand heavy loads and harsh operating conditions, providing enhanced durability and longevity.

- Reduced Maintenance Costs

High-quality bearing housings require less maintenance and are less prone to failure, reducing maintenance costs and downtime.

- Improved Performance

Quality bearing housings ensure optimal alignment and protection for bearings, leading to improved performance and efficiency of the equipment.

- Increased Lifespan of Bearings

By providing proper support and protection, quality bearing housings extend the lifespan of bearings, reducing the need for frequent replacements and associated costs.

How to Maintain Bearing Housings

Proper maintenance of bearing housings is essential to ensure their performance and longevity. Key maintenance practices include:

- Regular Inspection

Regularly inspect bearing housings for signs of wear, damage, or misalignment. Early detection of issues can prevent more serious problems and costly repairs.

- Proper Lubrication

Ensure that bearings and housings are properly lubricated according to manufacturer recommendations. Proper lubrication reduces friction, wear, and the risk of overheating.

- Cleaning and Replacement

Keep bearing housings clean and free from contaminants. Replace worn or damaged housings promptly to maintain optimal performance and prevent damage to other components.

Conclusion

Choosing the right bearing housing is crucial for the performance and longevity of your mechanical systems. By understanding the different types of bearing housings, the materials used, and the key factors to consider, you can make an informed decision that meets your specific needs. Quality bearing housings not only enhance durability and performance but also reduce maintenance costs and extend the lifespan of your bearings.

FAQs

1. What is the difference between a pillow block housing and a flange housing?

Pillow block housings are designed to provide support for a rotating shaft on a flat surface, while flange housings are mounted using flanges for additional support and stability against vertical or horizontal surfaces.

2. How do I choose the right material for a bearing housing?

Consider the operating environment, load capacity, and cost when choosing the material for a bearing housing. Cast iron is durable and cost-effective, stainless steel offers corrosion resistance, thermoplastics are lightweight and hygienic, and bronze provides excellent wear resistance.

3. What are the benefits of using stainless steel bearing housings?

Stainless steel bearing housings offer superior resistance to corrosion, making them ideal for harsh environments such as marine, food processing, and chemical industries. They provide excellent durability and longevity.

4. How often should I inspect and maintain bearing housings?

Regular inspection and maintenance are essential for the performance and longevity of bearing housings. Follow manufacturer recommendations for lubrication and cleaning, and inspect housings regularly for signs of wear, damage, or misalignment.

5. Why should I choose Abbott Ball for my bearing housing needs?

Abbott Ball offers a wide range of high-quality bearing housings designed to meet various application requirements. Their products are known for their durability, performance, and reliability, ensuring optimal performance and longevity for your mechanical systems.