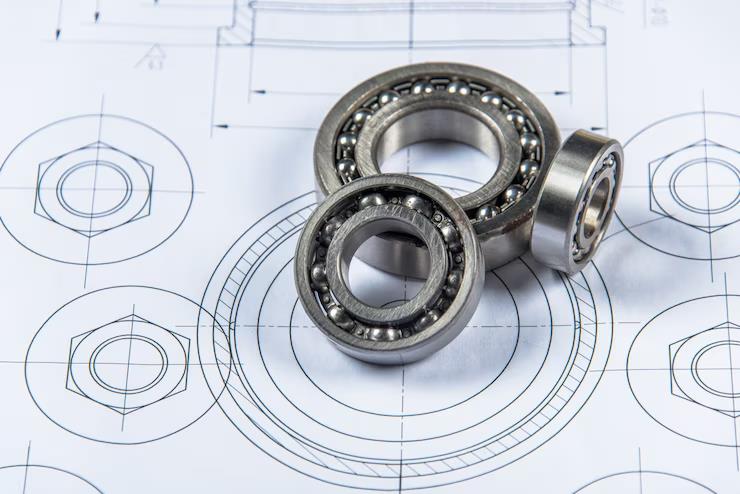

Introduction: Understanding the Significance of Material Selection in Ball Bearings

Ball bearings are a crucial component in numerous industrial applications, from aerospace and automotive to electronics and medical equipment. The selection of the right material for ball bearings can significantly impact their performance, longevity, and suitability for specific environments. This comprehensive guide delves into the key considerations for choosing the optimal material for ball bearings, backed by data and expertise.

Material Properties and Their Impact on Ball Bearing Performance

The choice of material for ball bearings is primarily influenced by factors such as load capacity, speed, temperature resistance, and environmental conditions. Common materials used for ball bearings include steel, ceramic, and plastic. Understanding the properties of these materials can help in making informed decisions.

| Material | Durability | Temperature Resistance | Load Capacity |

|---|---|---|---|

| Steel | High | Moderate | High |

| Ceramic | Very High | High | Moderate |

| Plastic | Moderate | Low | Low |

Steel Ball Bearings: Versatility and Reliability

Steel is the most widely used material for ball bearings due to its exceptional load-bearing capacity and versatility. Studies show that over 80% of industrial ball bearings are made from stainless steel or chrome steel, providing a balance between cost and performance.

Steel bearings are ideal for high-speed environments and applications where strength and durability are paramount. For more information, visit Abbott Ball’s contact page.

Ceramic Ball Bearings: High Performance in Challenging Conditions

Ceramic ball bearings are favored in applications requiring high-temperature resistance and corrosion tolerance. According to industry reports, ceramic bearings exhibit 40% less density than steel, resulting in reduced friction and improved speed capabilities.

The high cost of ceramic materials often limits their use to specialized fields like aerospace and precision machinery. For custom or standard materials that fit any application, consider Abbott Ball’s request quote service.

Plastic Ball Bearings: Cost-Effective Solutions

Plastic ball bearings provide a lightweight, corrosion-resistant alternative for low-load and low-speed applications. They are often used in industries where noise reduction is a priority, such as consumer electronics and medical devices.

Plastic bearings can be manufactured in a range of formulations to enhance specific characteristics, such as chemical resistance or operating temperature range. For tailored packaging solutions, Abbott Ball offers customizable options.

Understanding the Role of Coatings in Enhancing Bearing Performance

Coatings such as PTFE or ceramic can augment the intrinsic properties of ball bearings, offering advantages like enhanced corrosion resistance and reduced friction. Coatings are particularly beneficial in harsh environments, extending the service life of the bearing.

Assessing Environmental Impact and Sustainability

As industries push towards sustainability, the environmental impact of materials used in ball bearings becomes significant. Sustainable choices, including the use of recycled steel or innovative biodegradable materials, are gaining traction in new product development.

Economic Considerations: Balancing Cost and Quality

Cost is a critical factor in material selection. While steel remains the most cost-effective option for most applications, ceramic and plastic bearings, though expensive, offer long-term benefits that can justify the initial investment in specialized scenarios.

Comparative Analysis of Material Performance Over Time

Material longevity and performance under stress are critical for applications where maintenance access is limited. For example, ceramic bearings have a lower wear rate compared to their steel counterparts, which can result in a longer operational life and reduced maintenance costs.

Key Takeaways

The right choice of material for ball bearings is a strategic decision that affects performance, longevity, and cost. By understanding the unique properties and benefits of various materials, companies can optimize their bearing design to meet specific application needs. For more detailed discussions or to inquire about specific needs, Abbott Ball provides excellent resources through their contact and quote request portals, ensuring that your production process stays on the right track with customized solutions.

Frequently Asked Questions

What are the primary factors to consider when choosing ball bearing materials?

The primary factors include load capacity, speed, environmental conditions, temperature resistance, and cost. Steel bearings are preferred for high-load applications, while ceramic bearings are suitable for high-speed and high-temperature environments. Plastic bearings, on the other hand, are ideal for applications where weight and noise reduction are crucial. Understanding these factors can guide the selection process to ensure that the chosen material aligns with the application’s demands.

How do material properties influence the performance of ball bearings?

Material properties such as hardness, toughness, and thermal conductivity directly impact a ball bearing’s performance. For instance, steel offers excellent load-bearing capacity and durability, making it suitable for heavy-duty applications. Ceramic materials provide high-temperature and corrosion resistance, enhancing performance in extreme conditions. Plastic materials offer noise reduction and lightweight properties, beneficial in consumer electronics and medical devices. By analyzing these properties, one can tailor the material choice to optimize operational efficiency and longevity.

What are the benefits of ceramic ball bearings over steel ones?

Ceramic ball bearings boast several advantages over steel bearings, including reduced weight, lower friction, and higher thermal resistance. These properties make them ideal for high-speed applications where temperature fluctuations are significant. Although more expensive, their long-term reliability, reduced wear, and maintenance frequency often outweigh the initial investment. Ceramic bearings are especially popular in industries requiring precision and high-performance under challenging conditions, like aerospace and advanced manufacturing.

Why are coatings important in ball bearing materials?

Coatings play a critical role in enhancing the properties of ball bearings. They offer additional protection against wear, corrosion, and friction, extending the bearing’s life in harsh environments. Coatings can also improve lubricity and reduce the maintenance needs associated with bearing operations. Industries such as marine, where exposure to corrosive elements is frequent, benefit significantly from coated bearings, maintaining optimal operation and reducing downtime. Selecting the right coating can greatly enhance the performance and durability of the bearings.

Are plastic ball bearings suitable for high-stress applications?

Plastic ball bearings are generally not recommended for high-load or high-stress applications because they lack the strength and durability of metal bearings. However, they are suitable for environments where corrosion resistance, chemical exposure, and noise reduction are prioritized over load-carrying capacity. Plastic bearings are used effectively in medical devices and consumer electronics, where they provide significant benefits due to their lightweight and quiet operation. When selecting materials for high-stress applications, it is important to consider these limitations and compare them against other options like steel or ceramic bearings.